Over time, the fiberglass gelcoat on your boat can break down. Constant UV exposure causes normal wear, but coming into a dock too fast, misplacing drill holes, or dropping a boat anchor can also cause damage that requires fiberglass gelcoat repair.

Fortunately, you can patch up most minor problem areas with the right approach and supplies. In this complete guide to fiberglass gelcoat repair for your boat, we’ll outline the best practices for making gelcoat repairs so you can get your boat back on the water in no time.

Consult your owner’s manual for specific precautions related to fiberglass gelcoat repair for your boat. If your boat needs more than minor repairs and it might be time to say goodbye, check out the recently released Nepallo pontoon boats.

What is a Gelcoat on Fiberglass Boats?

Gelcoat is a layer of a resin-based polymer applied to the boat’s exterior. This polymer can have an epoxy base or a polyester base and is typically applied during the fiberglass molding process during boat construction. From a visual perspective, it gives your boat a smooth and shiny finish.

In addition to providing a glossy finish, gelcoat creates a waterproof barrier that reduces UV damage and hydrolysis (a chemical decomposition resulting from exposure to water). Thus, it is extremely important in maintaining the long-term structural integrity of your boat.

Why Use Gelcoat on Fiberglass?

Whether from normal wear and tear or a boating accident, your boat’s gelcoat can become compromised. That can look like anything from hairline cracks to larger chunks removed as a result of heavy impacts.

Your boat’s hull is particularly susceptible to gelcoat wear because it sees the most exposure to water. It is also the most likely area to be impacted by invisible underwater hazards. By repairing areas of damaged gelcoat, you are protecting the underlying structure of your boat for years to come.

Before you start repairing minor gelcoat imperfections topside, dry dock your boat and inspect it completely to understand the full extent of the fiberglass gelcoat repair work you’ll need to complete.

Can You Apply Gelcoat Over a Fiberglass Boat?

The short answer is yes. However, things get tricky if the part of your boat that’s damaged is textured or finished with a multi-tone coloring agent. Surfaces like diamond non-skid require extra attention.

Additionally, particularly deep holes in your boat’s exterior could require structural fiberglass repairs or a more solid filler before gelcoat repair can be done. For all of these instances, it is best to consult a boat repair expert.

That being said, on other surfaces, you can certainly make a fiberglass gelcoat repair on your own. Keep in mind that vertical surfaces make things a little harder and necessitate the use of a thicker gelcoat paste. For horizontal surfaces, you’ll be fine with a liquid gelcoat solution.

Recommended Tools for Fiberglass Gelcoat Repair

Depending on the extent of repairs you need to make, this process could take several hours. Here is a general list of the tools and supplies you’ll need to repair the gelcoat on a fiberglass boat:

- Gelcoat resin and catalyst

- Coloring agents

- Acetone

- Masking tape

- Handheld grinder and appropriate bits

- Countersink bit and drill motor

- Mixing cups

- Latex gloves

- Stir sticks

- Dust mask

- Putty knife

- Wet/dry sandpaper (320, 600, and 1,000 grit)

- PVA curing agent

- Rubbing/cutting compound

- Boat wax

- Cleanup rags

Please consult your boat’s owner’s manual for advisories and recommendations on specific gelcoat products. Once you’ve chosen a gelcoat product, read the instructions carefully to make sure you have the essential supplies at hand to complete a fiberglass gelcoat repair properly.

How to Repair Gelcoat On a Fiberglass Boat

These steps will prepare you to repair most gelcoat issues on a fiberglass boat.

Step 1: Know Your Boat Finish

Figure out whether the exterior of your boat is painted or already consists of a gelcoat, fiberglass, or polyester resin finish. If your boat is painted, you’ll need to remove the paint using a sander before starting your fiberglass gelcoat repair.

Step 2: Match Gelcoat Color to Boat’s Exterior

If you buy a generic gelcoat, you will need to add a coloring agent to match its color to your boat’s exterior. However, you can save yourself this step by contacting your boat’s manufacturer or the dealer where you purchased your boat. Ask them for a recommended gelcoat that matches your boat.

If you can’t track down a matching gelcoat, look for a gelcoat repair product that comes with several colored pigments you can add to the resin. In plenty of natural light, compare those pigments to your boat’s exterior to find the closest match.

Step 3: Get the Surface Ready

To prepare the surface, you’ll need to know how to remove gelcoat from fiberglass boat surfaces. Acetone is a great thinner to help you remove a thin gelcoat layer to repair smaller scratches, but extra work will be required for deeper damage.

For all scratches and gouges, remove the final layer of gelcoat from an area that is about twice the diameter of the actual damage. If repairing a deep gouge, use a power drill with a cone-shaped grinding bit to turn the damaged area into a V-shaped notch.

This notch will improve the filler’s ability to bond with the surface. And finally, use 80-grit sandpaper to remove loose chips of gelcoat and smooth out the bevel around the damaged area. Clean the area with acetone upon completion.

Step 4: Tape and Sand the Damaged Area

Use masking tape to create a border around the damaged area. This helps to protect undamaged areas from gelcoat splatter and it also helps you stay within the boundaries when sanding the area.

If using a spray gelcoat solution, you’ll want to tape off and protect a larger area. Spray-on applicators are more likely to cause splatter than paint-on solutions. Once the area is taped, sand with 360-grit sandpaper. Clean the area with acetone to complete this step.

Step 5: Apply Filler

This step is only necessary for deep gouges and scratches.

Use resin and an epoxy-based filler to fill the scratch or gouge. Epoxy-based fillers, although less cost-effective, are recommended over polyester-based fillers because they offer better adhesion and long-term durability.

Once filled, allow the filler to dry completely before re-sanding the area and cleaning again with acetone.

Step 6: Mix in the Catalyst

The correct ratio of gelcoat base to catalyst will depend on the product you’re using. Most products use a 2-to-1 ratio, but consult the instructions to determine the recommended ratio before mixing in the catalyst. Do this after adding any pigments or coloring agents to match the gelcoat to your boat’s exterior.

Adding too much or too little of the catalyst will hinder your gelcoat’s ability to adhere to your fiberglass boat. That said, you do have control of the viscosity of your gelcoat. How thick or thin you mix it will depend on the method of application and the type of surface you’re working on.

For vertical surfaces, many people prefer a spray-on application method because it limits dripping and helps to apply a more even coat. If you’re using another method of application, a thicker mix can help you limit dripping as well.

Step 7: Apply Gelcoat

Most people use a wooden or plastic putty knife to spread the gelcoat evenly over the affected area. There are also spray-on and brushed applications, which we’ll touch on below. Note that you’ll have 10 to 15 minutes to apply the gelcoat after adding the catalyst. If you wait too long, it will harden and be nearly impossible to apply smoothly.

Spray-on Application

Fill spray container with mixed gelcoat and attach air compressor hose. Start from the center of the damaged area and work your way outward. Use short strokes to apply the gelcoat as evenly as possible.

With most gelcoats, you’ll need to apply five or six layers to achieve the desired thickness. Wait at least 20 minutes between layers to allow the previous application to dry completely.

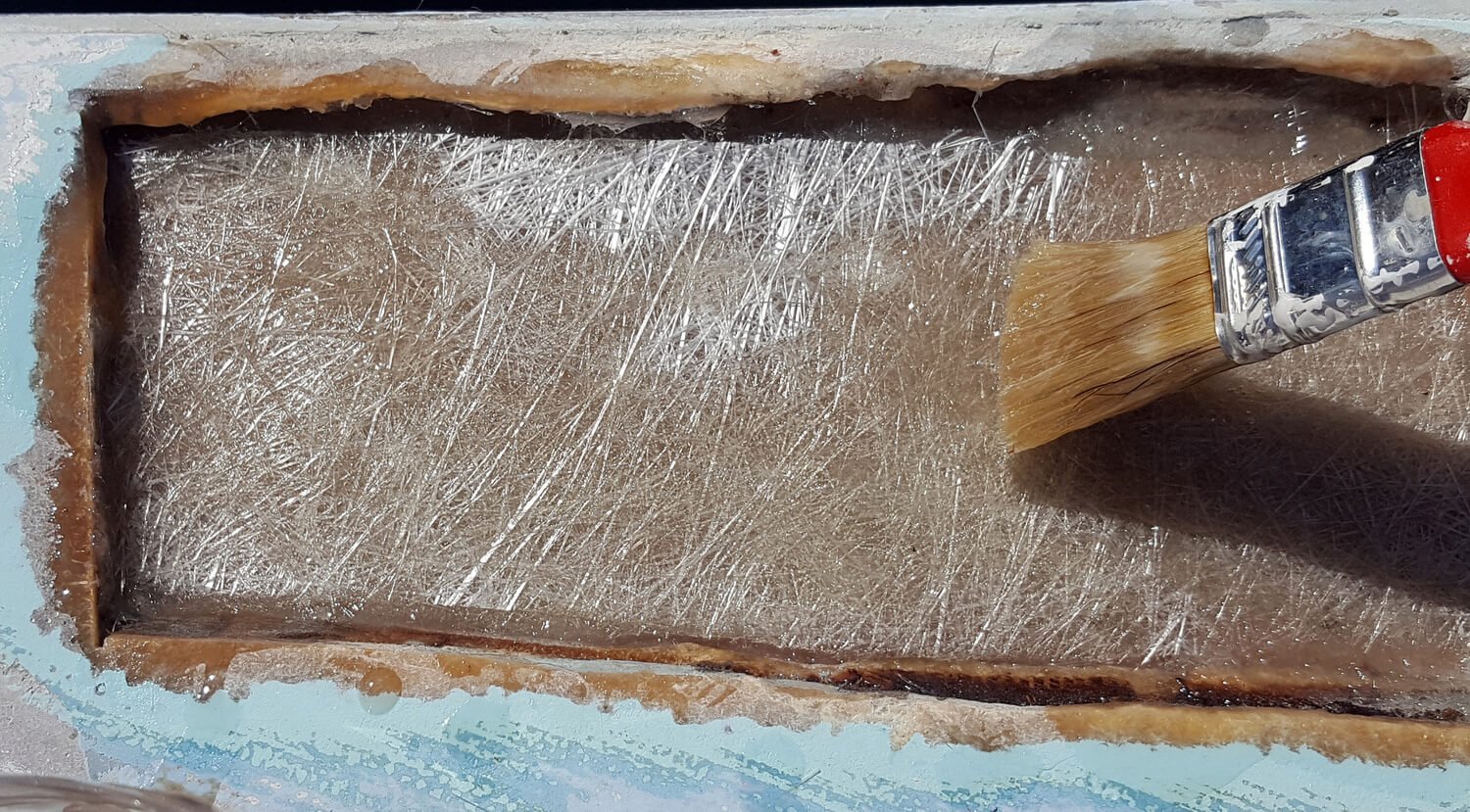

Brushed Application

Foam brushes or rollers are better for reducing drips and noticeable brushstrokes. Apply in short strokes vertically and apply enough layers to build a film that’s slightly higher than the surrounding area. This accounts for sanding the area down.

After the final layer dries completely, apply a PVA curing agent over the affected area. Let this agent dry completely according to product specifications.

Step 8: Sand and Finish

Start by removing that curing agent and then use a soft block to sand the entire area using a 320-grit wet/dry sandpaper. Then switch that out for a 600-grit paper and wet sand the affected area again to bring it flush with the rest of your boat.

Install that 1,000-grit sandpaper and take another sanding pass before buffing the area with a cutting compound. Buff the area gently with minimal pressure. Using too much pressure during this stage creates heat that can stain the surface. To finish, apply a single coat of wax-based gelcoat polish.

Spring is a great time to take care of your boat’s fiberglass gelcoat repair needs. Once you’re done, you’ll be back on the water and enjoying another full summer of your favorite watersports!

Have you patched the gelcoat on your fiberglass boat in the past? Let us know about your process in the comments below!

If you’ve recently purchased or are in the market for a new pontoon boat, read some more tips on how to maintain a pontoon boat properly!

[…] of your boat rubbing against the dock or other boats, boat fenders absorb rubbing or impacts to protect your boat’s exterior and minimize paint scratches, dents, and […]

[…] should also clean all areas of the boat, inside and out. This will help keep your paint nice and prevent corrosion. There are many commercial boat cleaning products out there, but most of the […]

[…] If you leave your boat in the water at the dock year-round, you need to stop ice from forming around the boat. When the water around your boat freezes, the water underneath is still running. The running water creates movement which causes the ice to rub against the hull. Hull damage usually starts as superficial scratches, but these scratches can develop into gouges and leaks if not cared for properly. […]