It doesn’t matter if you’ve been boating for years or if it’s your first time out; running into the dock is something everyone will experience at one point or another. However, it doesn’t have to be an issue. If your dock is protected, you won’t think twice about it. If your dock is not protected, you could be left with a costly repair bill.

Don’t leave your boat and dock susceptible to damage; learn about dock bumpers and edging with our comprehensive guide.

Purpose of Dock Edging and Bumpers

Judging speed and distance while on the water can be difficult, especially when you mix in other factors, such as rough wakes. You won’t always get this right, which can result in contact between the dock and your boat’s hull. Usually, your boat’s hull takes the worst of it, and unfortunately, that often costs the most to repair. Hopefully, you get away with a minor scratch, but hitting the dock hard enough or at the corner could lead to punctures, which might ruin your boating season.

The purpose of installing edging or bumpers on your dock is to protect your boat and the dock. It can be difficult to make the right choice, so let’s review it below.

Types of Dock Bumpers and Edging

There are many different types of dock edging and bumpers. If you are new to boating, the wide variety of shapes and sizes can be overwhelming. To choose the correct protection, you must consider several factors, such as wake condition, the boat’s size, the dock’s shape, etc. For example, docks with frequent water level changes may require a different edge than a dock in relatively calm water. If you have a large boat, you’ll want to use heavy-duty edging to absorb the shock properly.

Dock Edging Profiles

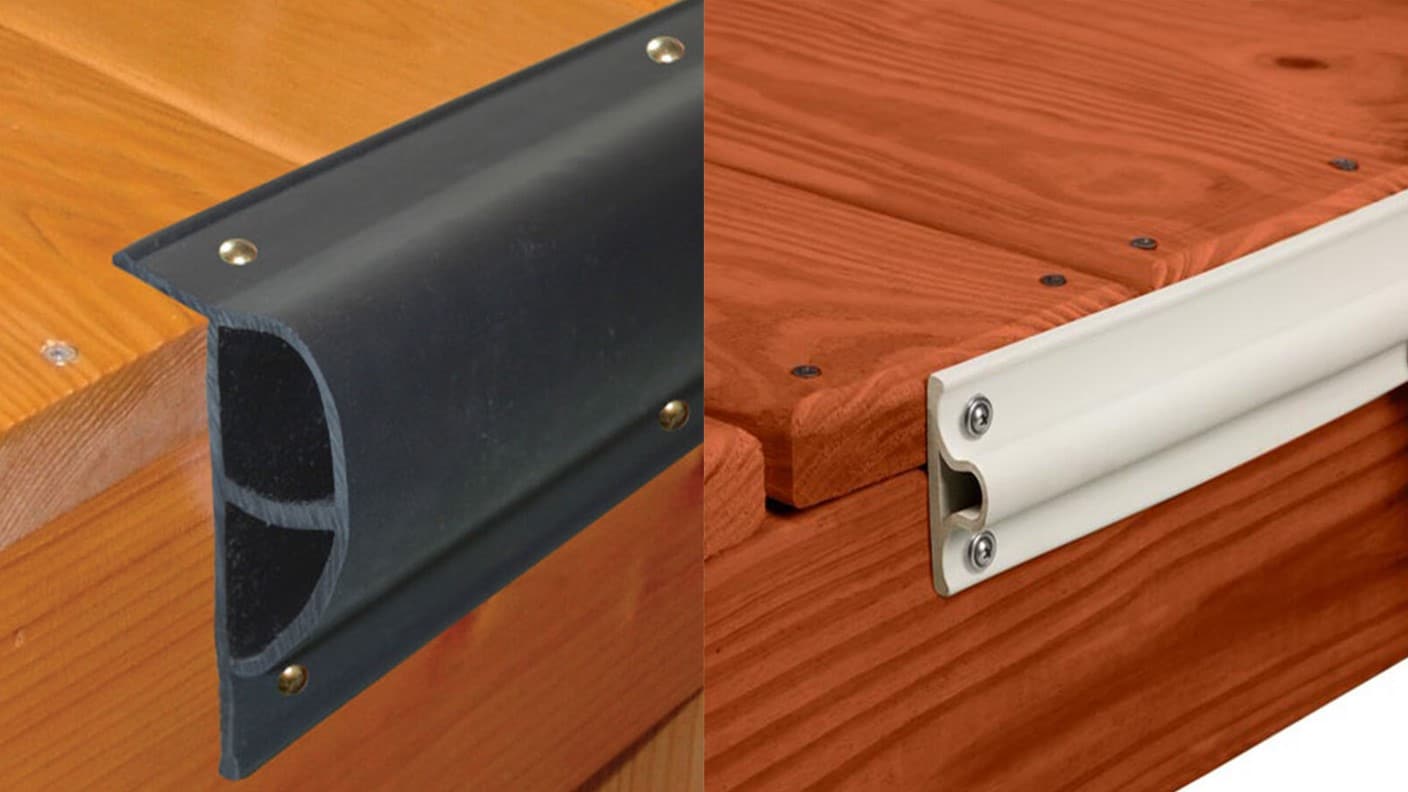

Two of the most common profiles you will see when looking at dock edging are D-shaped and P-shaped. The most significant difference between them is the coverage they provide. Let’s look at some pros and cons of each.

The advantages of D-shaped edging are as follows:

- Can be installed on round pilings

- Great for docks with taller sides

The advantages of P-shaped edging are as follows:

- Extra top lip protection

- Easier installation

It’s also important to consider the cons to determine which option is best for you.

The disadvantages of D-shaped edging are as follows:

- More challenging installation

- Top edge of deck left unprotected

The disadvantages of P-shaped edging are as follows:

- Cannot be installed on round pilings

- Traps debris under the top lip

- May interfere with dock accessories

To simplify, if you have a dock with tall sides, you should consider D-shaped edging, as you can position the edging further down for better protection. If you have shorter sides, consider P-shaped edging due to the additional coverage.

Ultimately, it comes down to your preference and specific setup, so choose wisely to ensure adequate coverage and protection.

Corner Bumpers

If there’s one area on your dock you really don’t want to run into, it’s the corner. Corners cause the most damage due to the sharp point so better protection is necessary here. There are several options for this type of protection, like mitering the edging, but a better option is specially molded bumpers, some of which can be placed over the existing edging. Another option, dock wheels help your boat roll forward into position.

Vertical Posts

Often referred to as pilings, vertical posts are another potential point of contact for boats. Therefore, you’ll need to cover these just as you do the sides and corners of the dock. Some edging can be installed vertically onto the pilings, but there are bumpers designed specifically for this purpose.

Closed and Open Core

Some edging may be completely open if you look inside, whereas others may be completely or partially filled. Edging with an open core is more pliable, so it’s easier to work with, but closed-core edging is more durable and offers better protection for heavier, larger boats. Closed-core edging is typically more expensive but will last longer.

Material

Many different materials are used in the production of dock edging and bumpers. The most common are PVC/vinyl, foam, and rubber. They differ in their durability and shock absorption properties. PVC is both durable and weather-resistant. It won’t fade or discolor over time. Foam is very cost-effective but lacks durability. Rubber is also a cost-effective material with great shock absorption properties but can cause scuffs on fiberglass hulls.

Installation

The installation of dock edging is simple; however, there are a few things to consider, such as the material of the dock and the type of screw. Stainless steel screws or nails are preferred due to their corrosion-resistant properties. The length will vary by your specific application, which is why hardware is often not included, and it’s up to you to find the appropriate type for your specific job. Depending on the dock edging brand, specific depth requirements may also exist.

You’ll likely need to measure and cut the edging to fit your exact dock, so be prepared to measure and have appropriate cutting tools. You may also need to pre-drill holes to help when securing fasteners.

Boat Fenders and Dock Edging

You may wonder if you need dock edging since you already have boat fenders. Boat fenders don’t usually account for dock corners or pilings, so you could still contact the dock even when using fenders. This is why it’s essential to have both boat fenders and dock edging, so you are protected in any case.

If you feel we missed anything, let us know in the comment below!

[…] Overton’s Shopper’s Guide to Dock Edging and Bumpers […]