In my experience, there are two types of trailer owners: those who religiously repack their bearings every year and those who can’t remember the last time it was done, if ever. The fact of the matter is that maintaining your boat is only half the battle. Your trailer requires just as much, if not more, attention to ensure you aren’t stuck on the side of the road while everyone else is out on the water having fun. In this article, we’ll go over everything you need to know in this trailer maintenance guide.

Basic Boat Trailer Maintenance Guide

We’ll be focusing on a few key components in this article. Each of these plays an important role in getting your boat to and from the water safely. The more you inspect and maintain your trailer, the more confident and familiar with it you will become.

Tires

Tires are usually one of the biggest failure points on a trailer. Odds are, if you have owned a trailer for long, you’ve had at least one blowout. In order to prevent them, you need to know why they occur. I could write an entire article on trailer tires alone but will try to give you just the meat and potatoes below.

Usually, the cause of a blowout is improper inflation. Contrary to popular belief, trailer tires must be filled to the max psi listed on the sidewall while cold, no more and no less. We’ve all heard of others reducing tire pressure for lighter loads to improve ride quality, but you should not buy into this. Reducing pressure also reduces capacity which leads to heat build-up. Heat build-up causes the air inside to expand and that is what creates a blowout. The max fill psi listed on the sidewall was specifically formulated to be the optimal tire pressure with both temperature build-up and weight capacity in mind.

Unlike the tires on your tow vehicle, trailer tires don’t wear; they age. While your trailer is parked, you should be using tire covers to protect them from the sun. If your trailer sits for too long in the sun, the rubber can start to crack which, if not prevented, will lead to blowouts. Additionally, if your tires are more than 6-7 years old, they should be replaced. The age of any tire can be found on the sidewall – a four-digit code that represents both the week and year the tire was produced. For example, a tire with a date code of 2522 indicates it was made on the 25th week of 2022.

If you need replacements, be sure to check out our selection of trailer wheels and tires.

Lights

Although your tires are typically the biggest failure point, lighting issues can be just as frustrating. They can be finicky and difficult to diagnose. Before every trip, you should have someone stand behind the trailer and verify each signal works as you progress through them in the tow vehicle.

If you find a light not working correctly, check the tow vehicle’s fuse box for the corresponding circuit. If all is good there, check the trailer connectors for bent pins or corrosion. If still no issues present themselves, check that the bulbs inside the taillights are in order. If all else fails, you’ll need to start tracing wires from the vehicle to the trailer looking for breaks or frays.

If you need to replace your lights, take a look at some of our trailer taillight options.

Hubs/Drums

Trailer bearings should be repacked every year. This requires lifting the trailer, removing the wheels, and disassembling the hubs. Then, simply clean out the old grease and repack with new grease. If you have a grease zerk on the end of your spindle, you can use this to add grease periodically, but we still recommend repacking once a year.

While you have the hub off, inspect the spindle shaft closely looking for nicks or discoloration. If damaged, you’ll need to replace the spindle or the axle entirely.

Take a look at some of our replacement hubs and drums if you need new ones.

Brakes

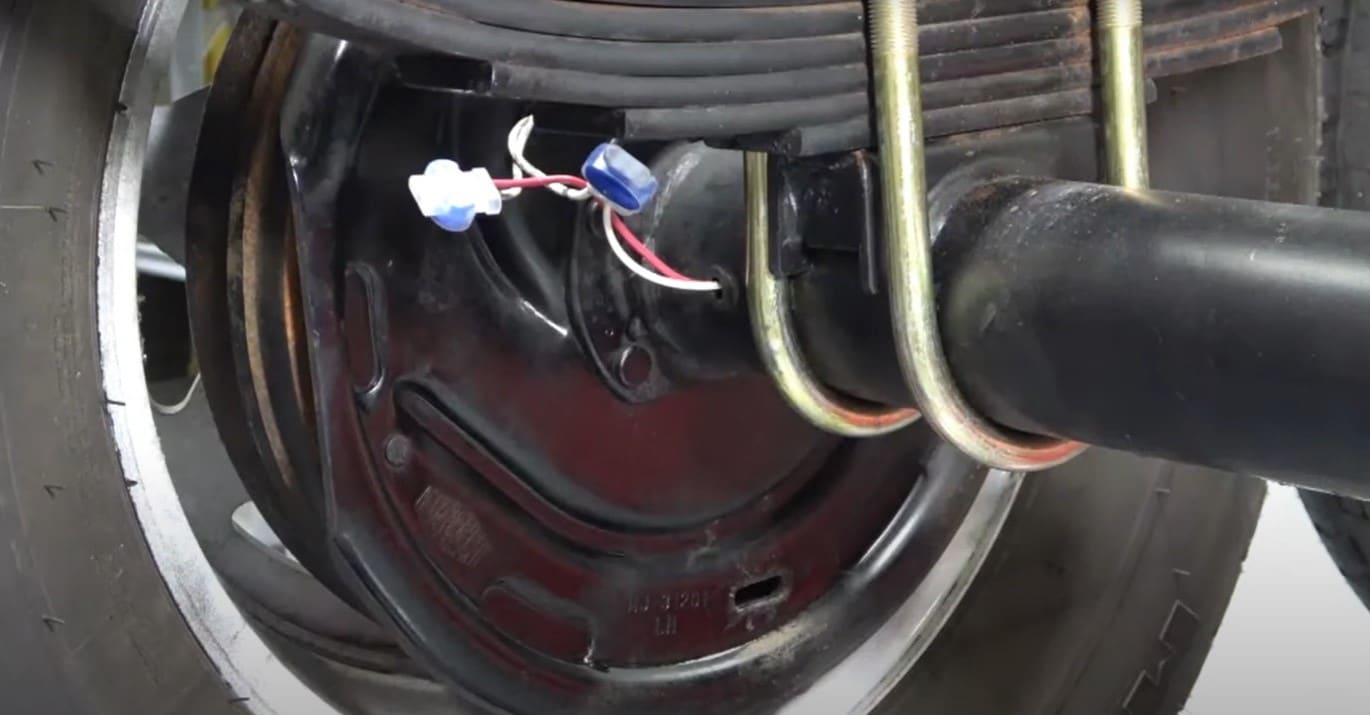

There are two types of brakes used on boat trailers: electric drum and hydraulic disc/drum. If you want to verify your brakes are working, you’ll first need to determine which type you have. If you see wires coming out of the back of your backing plates, you have electric brakes. If you see hard metal or soft rubber lines, you have hydraulic also known as surge brakes.

For electric brakes, apply the override at full power and listen to the hub for a “humming sound.” If you hear it, then you know the brakes are getting power. If not, you may need to check, using a multimeter, to be sure the brake controller in the vehicle is sending the proper signal as there may be a severed wire or faulty magnets.

For surge/hydraulic brakes, jack up one side of the trailer and spin the wheel. You should be able to stop the wheel with the coupler actuated. If not, you have an issue and would need to start looking over your lines and coupler for fluid leaks. It could be that you are just low on fluid or that the lines need to be bled. However, it could also be an issue with the coupler itself. In that case, the task of troubleshooting and repair is best left to a professional.

If you’re having issues, check out our replacement trailer brakes.

Winch

Your winch serves an important role in launching your boat and retrieving it from the water. A good place to start when looking over your winch is the cable/strap. Check this closely to ensure there are no frays; if so, replace it immediately. It could break if not cared for properly and cause damage to you, your boat, or a loved one.

In addition to the cable/strap, you’ll also need to look over the gears, bearings, springs, and pawls to make sure all are intact and working properly. This is a great time to clean everything and reapply grease or oil as instructed by the manufacturer.

If you need a replacement, check out some of our trailer winch options.

Coupler

Inspecting your trailer coupler may not be as straightforward as some of your other components. It will vary greatly based on what type of brakes you have, if any at all. For example, if you have electric brakes or no brakes, then your coupler is likely going to be very basic, whereas if you have surge brakes, your coupler has much more going on with tons of small moving parts.

No matter which coupler you have, your primary focus should be the latching mechanism. You’ll want to check this often as a malfunction could lead to catastrophic failure. If you experience trouble latching once on the ball, if you can see penetrating rust beyond the surface, or if there is too much slop or play within the coupler while attached to the ball, it’s time to replace it.

In addition to the coupling mechanism, you’ll also want to check how the coupler is attached to the trailer. If welded, make sure the weld is continuous and there are no breaks or cracks. If bolted, look over the condition of the hardware and check for proper torque using a torque wrench.

Finally, if you have a surge braking system, you’ll want to check for fluid leaking anywhere around the coupler. This is also a great time to get up to date on your coupler maintenance, lubing and/or greasing any components outlined by the owner’s manual, such as the inner slide member.

Leaf Springs

It can be easy to overlook leaf spring maintenance because they are, after all, just a flat piece of steel. However, like the other components listed above, they can go bad and require your attention. It’s important to catch potential issues ahead of time so they don’t leave you stranded on the side of the road.

The main thing to look out for is stretching. As they age, leaf springs will flatten out. This causes the trailer to sit lower which increases the chance of contact between the tire and fender. They can also weaken, and small cracks can form which can develop into larger ones, often resulting in a broken spring. You’ll need to look after the bushings located in the eye of the spring as well, since they can become oblong and require replacement.

Please note, leaf springs need to be replaced in pairs to ensure the trailer sits level. You’ll also want to replace your u-bolts when doing this job as they are torque-to-yield fasteners that should not be reused. If you have a torsion axle, you don’t have leaf springs, and you can disregard this step.

Tongue Jack

Your tongue jack is responsible for raising and lowering your coupler onto the hitch ball. If this is not working, you won’t be doing any boating anytime soon. They are typically maintenance-free, but there are a few things you need to watch out for.

If you feel the handle getting harder and harder to turn, you might be getting low on grease and need to add some. Unfortunately, most manual tongue jacks don’t have any sort of grease fittings, so you’ll need to remove the top cap or possibly the handle to get grease into the jack, depending on if it’s a top or side-wind. If you don’t stay on top of greasing, you’ll eventually strip the gears and will require an entirely new jack.

If you need a full replacement or simply don’t want to bother with trying to grease yours, you can take a look through our selection of replacement trailer tongue jacks.

Axle

There are two types of trailer axles, leaf spring and torsion. It should be easy to distinguish which you have. Torsion axles are square whereas leaf spring axles are usually round although can be square as well. There’s not much maintenance required on either. With a leaf spring axle, just make sure there are no noticeable bends. If you start to have irregular tire wear, this could be the result of a bent axle. Please note, most axles have a bow in the center which is not to be confused with damage.

Torsion axles have built-in suspension. If you notice the trailer sagging or a rough ride, these could be signs the rubber inside the torsion arm is worn and needs to be replaced. However, these last many years so it’s not something that should be checked too often.

Saltwater vs. Freshwater

Trailers that frequent saltwater should be cared for much more often than trailers used solely in freshwater. For starters, you should be rinsing your trailer and boat down each time you leave the water. This not only cleans any contaminants from the water off the boat, but it also helps remove any leftover salt.

Regarding replacement parts, make sure you’re using metals and coatings which offer the best corrosion protection such as galvanized and aluminum. This is especially important for the wheels, leaf springs, and axles.

Common Issues

Like your boat, boat trailers can be kind of a headache and problem-ridden at times if you aren’t doing everything right. One mistake I see at the boat ramp is backing your trailer into the water with the trailer connector still plugged into the vehicle.

This is an issue because on your way to the boat ramp, your lights emit heat. When you dunk the lights in cool water, the rapid cooling causes the light housing to suck in water. Water inside the light housing will short out your lighting circuits and create corrosion problems. If you back far enough into the water or make a big enough splash, you’ll also get water inside the connectors which will lead to corrosion problems and more lighting issues.

Popular Upgrades

Depending on what boat and trailer you purchased or how old it is, you may be lacking some modern amenities that can make your time to and from the water much easier. I have listed some of the popular options below that you may be interested in.

- Bearing Protectors – Often referred to as “Bearing Buddies”, these protectors are replacements for your grease cap and allow for easy greasing of your hubs. They also do a great job of keeping out water which is what makes them so popular for boat trailer owners. Please note, these won’t work if you already have easy lube spindles with grease zerks in the end or if you have oil bath hubs. If you would like to add bearing protectors to your trailer, measure your grease cap diameter and choose a set that matches.

- Tire Pressure Monitoring System – Tire pressure monitoring systems (TPMS) allow for easy monitoring of your tire’s internal pressure. This is important because it allows you to better detect and prevent blowouts. Most of these kits have alerts you can set to inform you when conditions for a blowout are imminent.

- Guide-Ons – Depending on your boat type and weather conditions, most can benefit from installing a set of guide-ons on their trailer to help with retrieving their boat. Most often found in the form of a PVC post, they help you aim your boat while loading so you can better center it on the bunks. They are simple in design but very effective in functionality.

- Spare Tire – If your boat trailer doesn’t have a spare wheel and tire, we highly recommend adding one. The last thing you want is to leave your boat stranded on the side of the road after a blowout. If you have towed long enough, you know blowouts are sometimes unavoidable. This is why it’s important to be prepared with a spare wheel and tire so you can change it out on the side of the road to get back up and running.

If you have any other tips for keeping your boat trailer maintained, let us know in the comments below.

[…] The Complete Maintenance Guide for Your Boat Trailer […]

[…] If you would like to dive into this further, check out The Complete Maintenance Guide for Your Boat Trailer. […]

[…] The Complete Maintenance Guide for Your Boat Trailer […]

[…] The Complete Maintenance Guide for Your Boat Trailer […]